New Challenges for the Global Supply Chain

Recent extreme weather events in Southeast Asia have sounded the alarm once again. Historic flooding in southern and central Thailand has severely impacted rubber-producing regions, while Vietnam and Malaysia are suffering from intense heatwaves, leading to a sharp decline in output. According to the latest data from the Association of Natural Rubber Producing Countries (ANRPC), the global rubber supply-demand gap will reach 700,000 tons in 2025—marking the fifth consecutive year of shortage.

These disasters not only disrupt supply but have also caused rubber prices to fluctuate dramatically in the past six months, rising over 35% compared to the same period last year. Meanwhile, the global shipping crisis remains unresolved, with freight costs staying high—putting unprecedented pressure on manufacturers that rely on overseas suppliers.

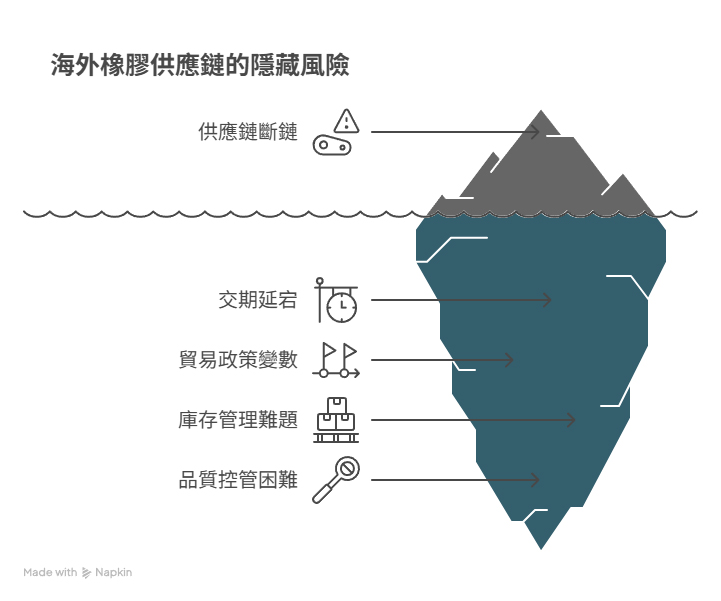

The Risks of Over-Reliance on Overseas Suppliers

Many companies have long relied on overseas rubber suppliers for cost reasons, but this strategy has revealed several hidden risks:

- Supply Chain Disruptions: Production lines can be forced to shut down due to extreme weather or political instability in supplier countries.

- Unpredictable Delivery Delays: In the first half of 2025, global shipping on-time rates were only 65%, meaning one-third of shipments were delayed.

- Tariff and Trade Policy Uncertainties: The upcoming EU Deforestation Regulation (EUDR) further increases the uncertainty of rubber trade.

- Inventory Management Challenges: To cope with unstable supply, businesses are forced to increase inventory, tying up more working capital.

- Quality Control Difficulties: Long-distance cooperation makes it harder to identify and resolve quality issues in a timely manner.

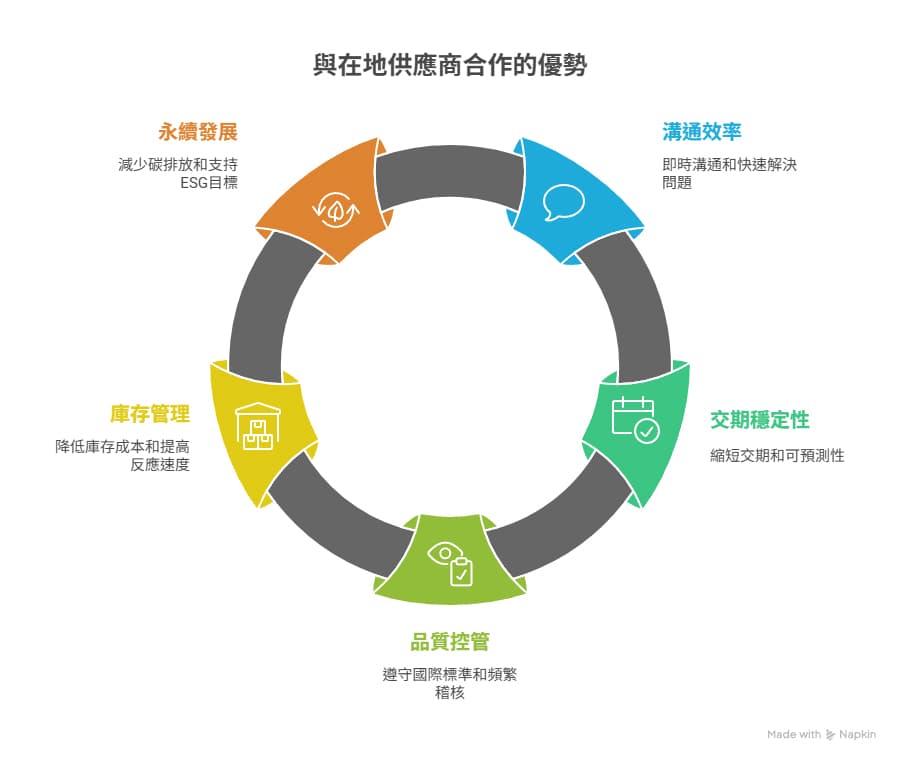

Five Key Advantages of Localized Supply

In response to these challenges, more companies are turning to local suppliers. Take XACE, a professional rubber manufacturer in Taiwan, as an example—partnering with local experts like them offers the following advantages:

- Superior Communication Efficiency and Flexibility

Real-time communication without time zone or language barriers makes changes and problem-solving much more efficient. One electronics manufacturer shared: “From submitting the request to receiving the sample, XACE took only one-third of the time compared to our previous overseas supplier.” - Reliable and Predictable Lead Times

Local supply chains greatly reduce logistics time. XACE’s average lead time is 15–20 days, much shorter than the 30–45 days typical of Southeast Asian suppliers, and unaffected by global shipping fluctuations. - Strict Quality Control and Standards

XACE follows international standards like ISO 9001, ISO 14001, and IATF 16949 to ensure consistent quality. Proximity also enables more frequent supplier audits. - Flexible and Efficient Inventory Management

XACE offers VMI (Vendor Managed Inventory) services for long-term clients—pre-stocking based on forecasted needs and delivering just in time. An industrial equipment manufacturer reported: “After working with XACE, our rubber component inventory costs dropped by 22%, while our supply chain responsiveness improved.” - Sustainability and Environmental Responsibility

Choosing local suppliers supports global carbon reduction efforts. Importing from Southeast Asia creates 2–3 times more carbon emissions than local sourcing. XACE actively promotes green manufacturing, contributing to customers’ ESG goals.

In an unpredictable global landscape, the stability of the rubber supply chain has become a key factor in manufacturing competitiveness. Choosing a professional local supplier like XACE in Taiwan can help businesses avoid international supply chain risks and improve product quality and innovation through close collaboration.

Wise business leaders should re-evaluate their procurement strategies—placing equal value on supply resilience and cost. A reliable local supply partner like XACE is the cornerstone for navigating turbulent times with confidence.